Description

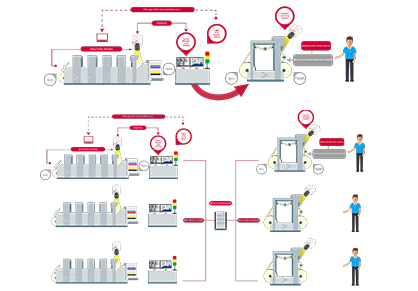

1. Inline Inspection and Waste Removal Workflows combines both inline inspection process control and offline waste removal into one cost-effective,automatic and efficient solutions for defect material handling.

2. Inline Inspection system is installed on printing machine,lamination machine or slitting machine to monitor real-time quality,prevent continuous waste and record all defect data into database.

3. After defect reviewing and editing,all the selected date will be transferred and downloaded to rewinder which will automatically stop on defect position for removal.Customer can choose for 1-to-1 workflow or N-to-N workflows on actual conditions.

Reviews

There are no reviews yet.